About Hot Melt Adhesive For Manual Edge-Banding

We are engaged as manufacturer and supplier of Hot Melt Adhesive For Manual Edge-Banding. These are used to fix wires in different electronic devices, coating label stock material, and are also used to assemble parts in various applications. This is used in varied packaging and is suitable for school handicrafts, home DIY, and electronic parts. Hot Melt Adhesive For Manual Edge-Banding is appreciated because of its qualities such as fast drying and fine finish. Moreover, it is available in an affordable range in the market.

Specification

|

Supply Ability

|

000

|

|

Shelf Life

|

000

|

|

Grade

|

000

|

|

Brand

|

MARIO

|

|

Color

|

White

|

|

Type

|

Ethylene-Vinyl Acetate

|

|

Packaging Size

|

25 KG

|

|

Material Compatibility

|

Paper

|

|

Usage/Application

|

Book Binding,Pressure Sensitive Applications,Packaging

|

|

Item Code

|

0000

|

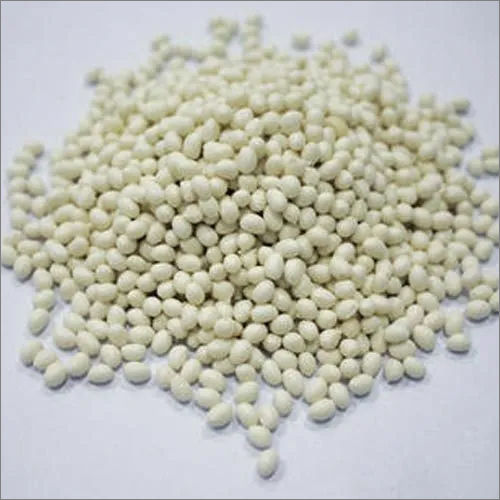

Engineered for Superior Edge-Banding PerformanceOur hot melt adhesive is tailored for manual edge-banding, providing a safe, effective, and efficient solution for woodworking professionals across India. With its polymer-based EVA formula, it delivers high purity (99%) and excellent thermal stability. Its moderate hardness ensures robust bonding without compromising flexibility. Suitable for application on wood, MDF, and particle board, this adhesive supports strong, lasting edges even under demanding conditions.

Optimal Application for Durability and StrengthThis adhesive is designed for use in manual edge-banding machines within the recommended temperature range of 160C to 190C. Its medium hardness and high tensile strength yield a bond that is both durable and reliable. A fast set time allows for increased productivity on the production floor, while its odorless, non-toxic composition ensures operator safety.

FAQ's of Hot Melt Adhesive For Manual Edge-Banding:

Q: How should I apply the hot melt adhesive for manual edge-banding?

A: For best results, use a manual edge-banding machine and set the application temperature between 160C and 190C. Apply the granules to achieve a glue thickness of 0.3-0.5 mm. Press the edging material onto the adhesive within the 15-30 second open time for maximum bond strength.

Q: What types of surfaces are compatible with this hot melt adhesive?

A: This adhesive is formulated for use on wood, MDF (medium-density fiberboard), and particle board, making it suitable for various furniture and cabinetry edge-banding applications.

Q: When can the bonded material be handled after application?

A: The adhesive sets in 40-60 seconds. After a minute, you can safely move or handle the bonded components without risk of the edges detaching.

Q: Where should I store the hot melt adhesive granules?

A: Store the granules in a cool, dry place at a temperature between 5C and 35C. Proper storage will maintain adhesive quality and extend shelf life up to 12 months.

Q: What are the benefits of using this industrial-grade EVA hot melt adhesive?

A: Key benefits include fast setting, strong bonding, high purity (99%), excellent heat resistance (up to 90C), odorless and non-toxic formulation, as well as superior holding power and tack retention. These features ensure reliable and long-lasting results in edge-banding projects.

Q: How is the adhesive supplied and what is the recommended packaging size?

A: The hot melt adhesive is supplied in solid granule form, packaged in convenient 20 kg bags. This facilitates easy handling, storage, and consistent feeding into manual edge-banding machines.

Q: What process ensures optimal bond strength during application?

A: Maintain the recommended application temperature (160C-190C), apply an even layer of adhesive (0.3-0.5 mm), and press the edging quickly during the open time (15-30 seconds) to create a strong, durable bond.